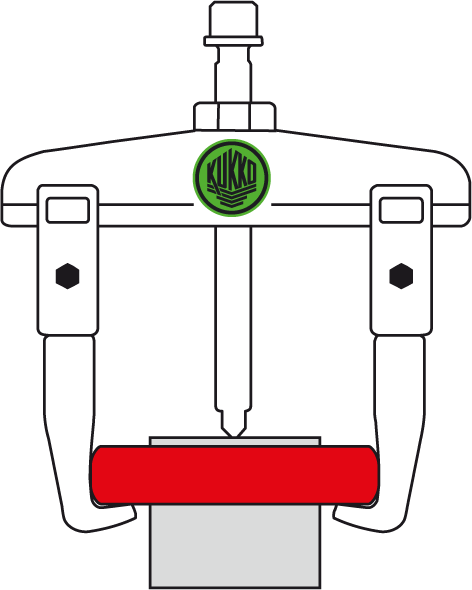

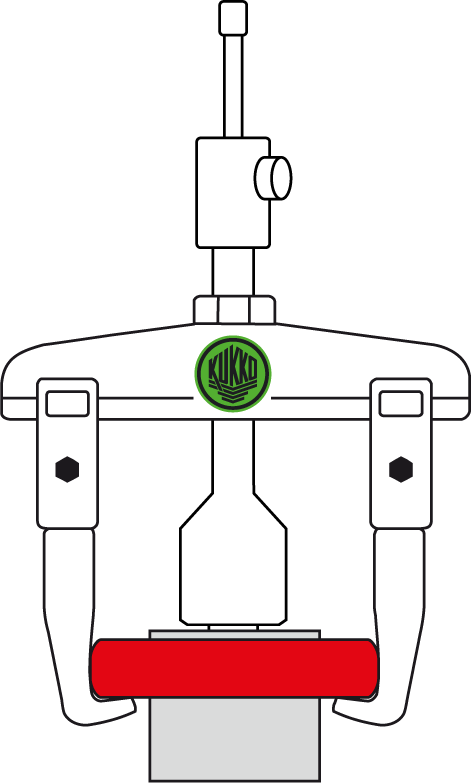

An especially common application of pullers is external extraction. Here, the part being removed (such as a gear, a pulley or a ball bearing) is gripped from the outside. By tightening the spindle, the part being removed is released from the shaft.

Standard external extraction.

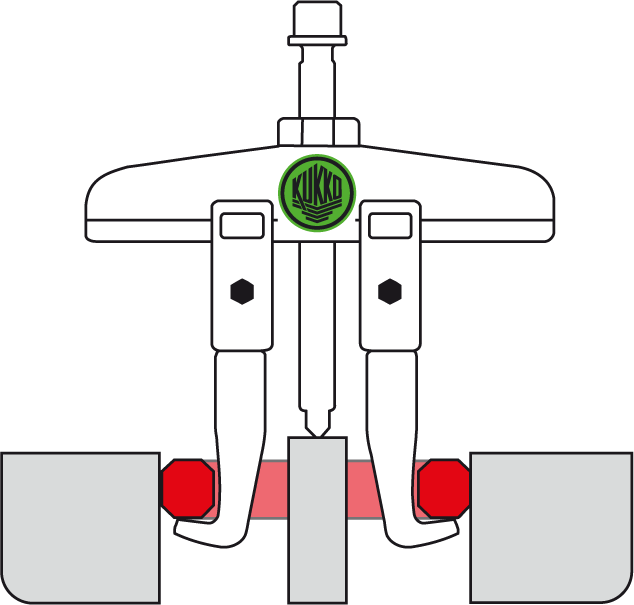

Pullers can be used for internal extraction by turning the jaws. It should be noted that, when using the puller as an internal puller, a fixed point in the middle is always required to support the pressure spindle.

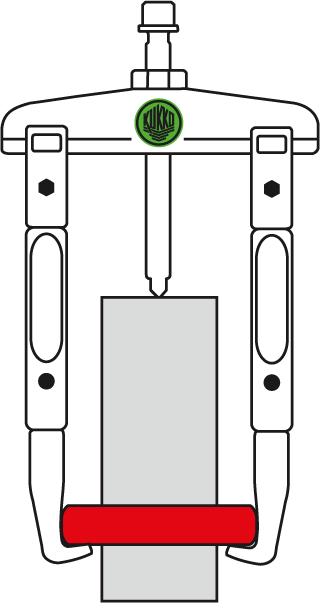

Accessories: Extensions

For series 20 and 30 products, KUKKO offers modular extensions (compatible with sizes 1 to 20). The extensions can be combined with one another and can be adjusted to fit the required clamping depth.

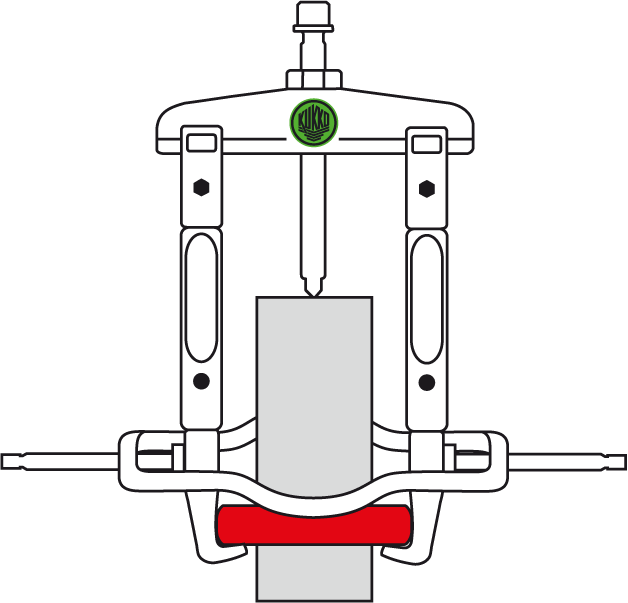

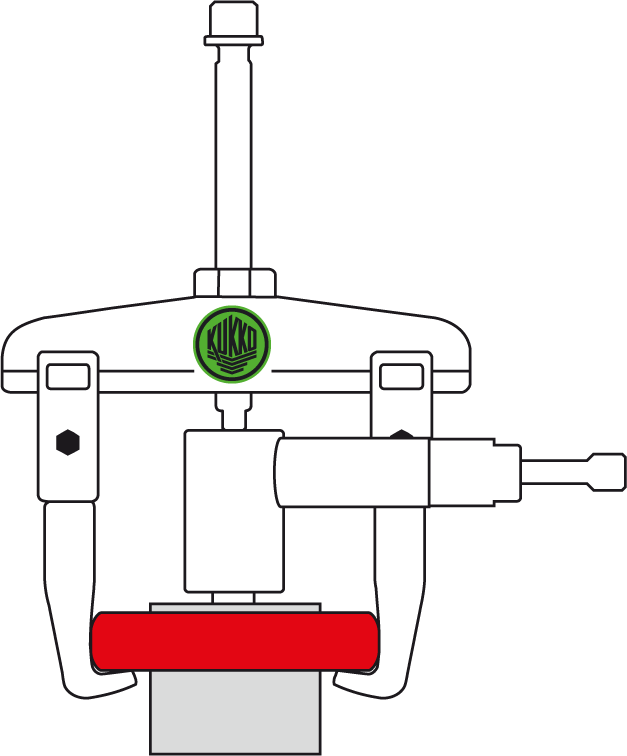

Accessories: Clamps

External removal using an additional clamp. This presses the jaws firmly to the part being removed and serves as a stability support during the removal process.

Accessories: Grease hydraulic spindle

The hydraulic spindle allows the 7-20 t to work in a controlled and safe manner. It uses the entire performance potential of the puller, going beyond the possibilities offered by mechanical spindles. Replacing the mechanical spindle with a hydraulic spindle also reduces the required driving force considerably.

For use with size 3 KUKKO mechanical pullers. The additional grease-hydraulic presses are a good tool for significantly increasing the pressure when removing very tight parts. The hydraulic presses are simply clamped between the spindle and shaft with the mechanical spindle. There is no need to modify the puller!

Notes on external removal

For central shafts, the puller needs to be set in the middle. If the shaft is not centered, it can also be removed asymmetrically with pullers with parallel jaws.

The slides of the jaws must always be completely and firmly seated on the cross-beam.

When removing multiple components, always remove them one at a time. Never remove multiple parts at the same time.rnrnIf there is enough clearance around the part being removed, we recommend using a 3-arm puller for optimum load distribution.

The contact surfaces of the jaws must be completely and evenly below the part being removed.rnrnA 2-arm puller is used when there is not enough free space for the 3-arm version.