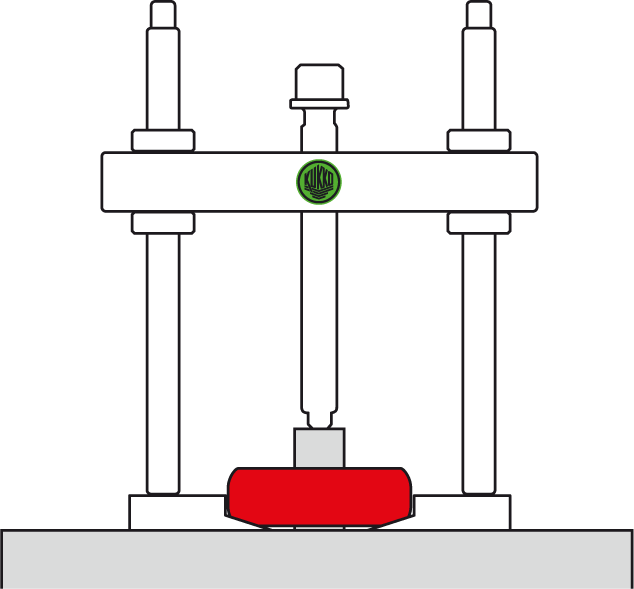

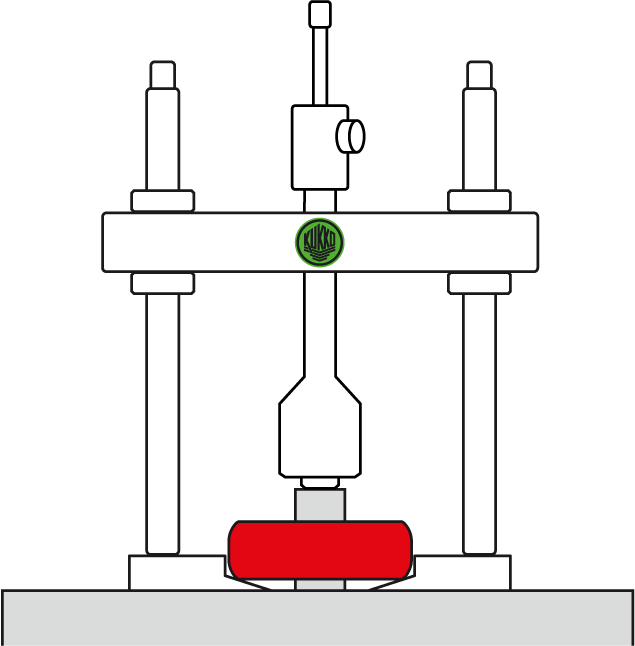

For removing flat-lying parts such as ball bearings, roller bearings, inner races and more. The sharp, wedge-shaped edges are pressed behind the part to be removed and slid between the bearing and the seat. For removal, the puller’s tension bolts (series 18) must be screwed into the separator.

Separation usually involves using a separator in conjunction with a puller.

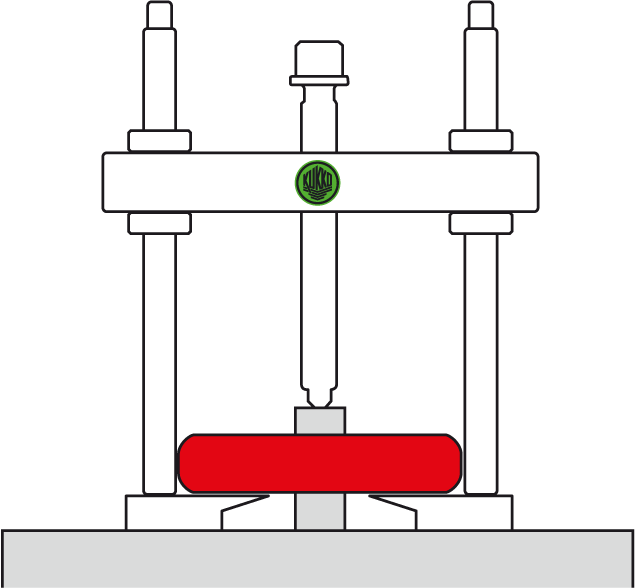

If you screw the separation jaws the other way around into the puller, the seating is enlarged and removed more gently.

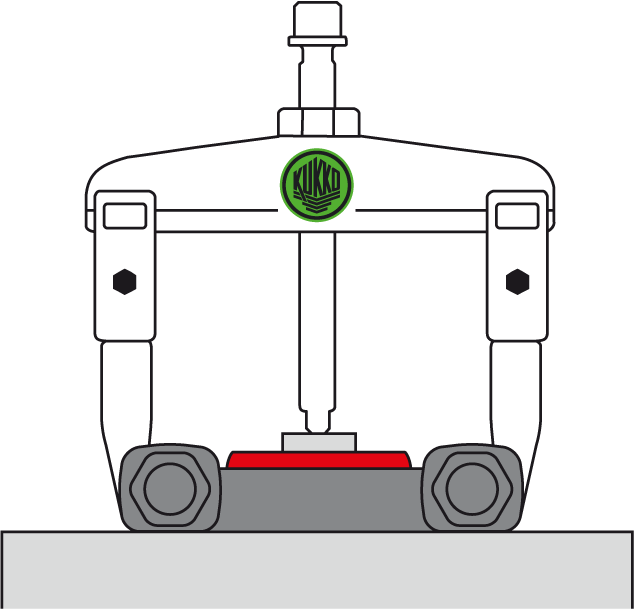

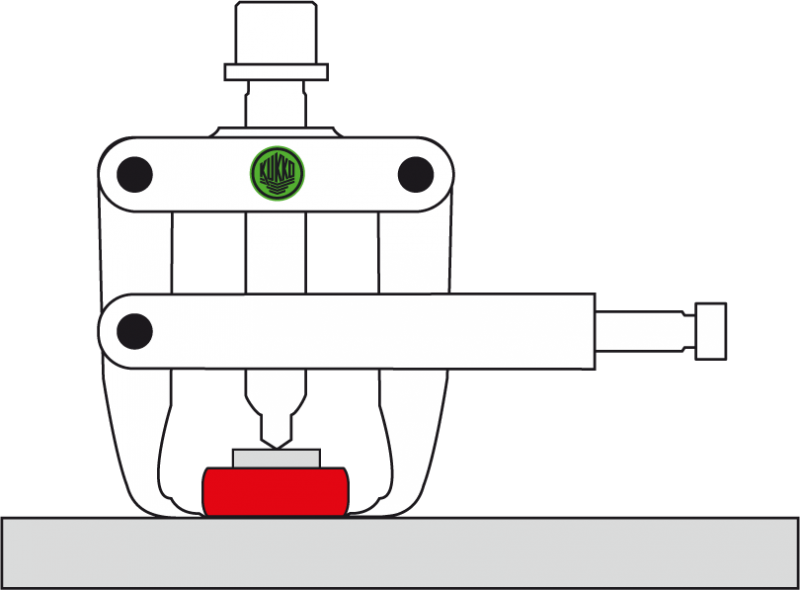

It is also possible to use a corresponding 20 series puller with the bearing separator instead of the puller tool.

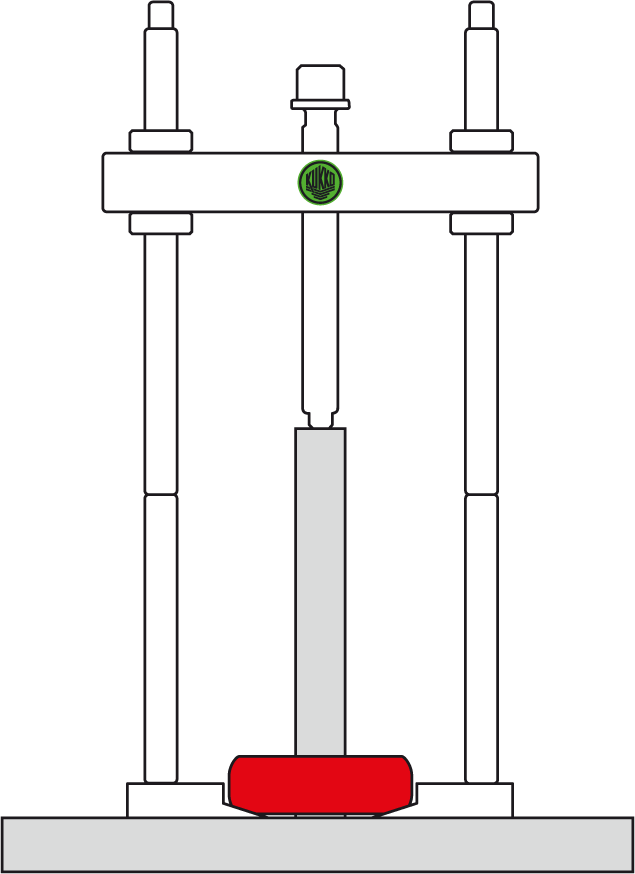

Accessories: Extensions

It is possible to extend the pullers. The extensions can be combined and adjusted to the required clamping depth.

Accessories: Grease hydraulic spindle

For particularly tight parts, the mechanical pressure spindle can be replaced with a hydraulic pressure spindle on larger models (from 18-2).

Some pullers in the KUKKO range, such as the 204 and 210 series “Cobra”, have separating claws.

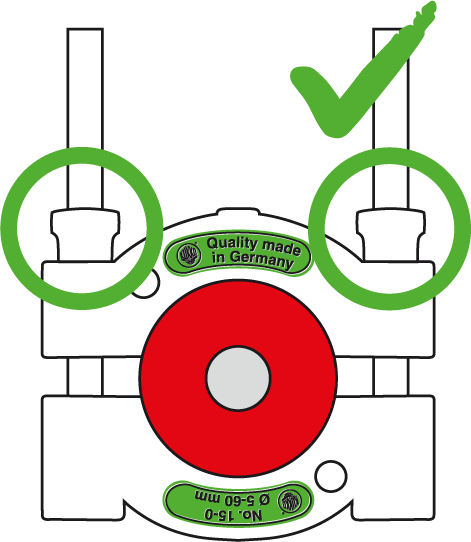

The adjusting nuts on the separator must be tightened uniformly in an alternating manner. This prevents the bearing separator from tilting on the spindle or the spindle thread from being damaged.

When tightening the separator blades, make sure they are seated as far as they will go under the part you are removing before pulling upward with the puller.

The jaws of the puller must always be screwed into the bearing separator as far as they will go.